Monobloc Aerosol Can Line

Base Coating Machine

This Machine is very compact and rigid in construction used to do base coating of Cans before printing. This machine is design in 10 stations turret with manifold indexer mechanism.

| Sr. Nos. | Technical Data | ||

|---|---|---|---|

| 1 | Min. & Max. Dia. Coating Cans Size | 25mm to 66mm | |

| 2 | Can Length Maximum | 250mm | |

| 3 | Speed Per Min Can | 60 | |

| 4 | Main Motors | 2HP | |

| 5 | Approx. Height | 1200mm | |

| 6 | Approx. Width | 1200mm | |

| 7 | Approx. Length | 1200mm | |

| 8 | Approx. Weight | 1500Kgs | |

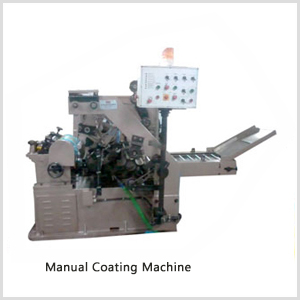

In manual machine Cans are auto feed by pusher feed mechanism with manual loading of Cans on conveyor, but after coating of Cans take out will be done manually. Fix dug drive speed and fix mandrel drive in manual machine.

In automatic machine Cans are auto feed by pusher feed mechanism with auto or manual loading of Cans on partition gravity conveyor. Pick-n-place mechanism will be used after wet base coating to transfer the Cans onto oven chain for drying. Dug drive is separate with geared motor variable drive. Mandrel Drive is separate & variable. Machine main drive is variable with gearbox 3HP as oven also driven for synchronization. This way we can run machine separately. No can no coat operation. If complete decoration line to be driven full auto with synchronization than common drive for coating, printing & varnish machine with oven can be designed. This way decoration unit works as single unit and not individual machine. Level of automation can be incorporated in decoration line as per client requirement

(a) One set of Mandrels