Aluminium Collapsible Tube Line

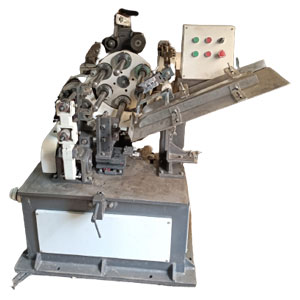

Automatic Trimming Machine

The Trimming machine is made very compact and sturdy in Construction. All the main shafts run on antifriction and heavy duty bearings which are selected for high speed and can take heavy load. The machine is driven by an incorporated electric motor, an endless V belt and intermediate reduction gear box. The spindle turret head is indexed by 8 station Manifold indexer Mechanism supports the bearing mounted plug-in mandrels. In the Tube finishing operation, the Mandrels at the working stations are rotated by nylon Sand witched Belt. Conveyor is also adjustable for Short and Longer Tubes. In this machine tubes are auto feed & unfeed by pusher mechanism. This machine is operated to finish the tube length, face, and nozzle, cut thread & debur after tube extruded from press.

| Sr. Nos. | Technical Data | |

|---|---|---|

| 1 | Minimum & Maximum Tube Size | 12mm to 35mm |

| 2 | Tube Length Maximum | 200mm |

| 3 | Speed Per Min Tube | 60 |

| 4 | Main Motor & Mandrel Motor | 3HP & 1HP |

| 5 | Approx. Height | 1200mm |

| 6 | Approx. Width | 1200mm |

| 7 | Approx. Length | 1500mm |

| 8 | Approx. Weight | 1200 Kg |

Manual Trimming Machine comes with pusher feed pusher take out and individual machine run with normal standard mandrels

Automatic Trimming Machine is manufactured with pusher feed, tube feed wedge with vacuum for holding, separate mandrel drive, separate buff motor, scrap collection blower, expansion mandrel, variable frequency drive, clutch control, machine synchronization with press speed to operate in full auto mode. System integration or level of automation can be designed to suit customer requirements.

Mandrels; Threading Chucks; Threading Cam; Knurling Screws; Shaving Tool; Grooving Tool; Facing and End Cutting Tool; Tube Releasers; Tube Striping Patti; Buffing Attachment; scrap collection blower