Aluminium Collapsible Tube Line

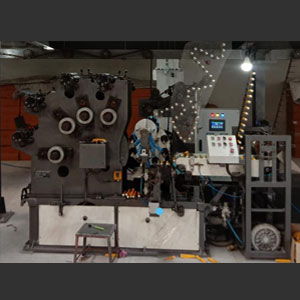

Four Colour Dry Offset Printing Machine

This Four Colour Dry Offset Printing Machine is designed for high quality printing at a high speed. This machine is design in 10 stations turret with manifold indexer mechanism.

The inking devices can work together or separately. The machine can be adjusted for three, two or single Colour Printing. The ink distribution can be regulated on one side, with adjusting for three, two or single Colour Printing.

The ink distribution can be regulated on one side, with the adjusting screws of the distributing roller and on the other side, through the ink adjustment on the Ductor Blades. All the Machine adjustment points are easily accessible and each Printing unit can be set independently of the other. For fine register adjustment is provided with the Plate rolls both axially and radially. The individual rubber inking rolls are easily detachable. The Zinc Plates are fixed firmly on both ends by means of retaining bars or rolls. The Printing Blanket is fixed securely at both ends to the Printing Cylinder and can be easily inserted.

| Sr. Nos. | Technical Data | ||

|---|---|---|---|

| 1 | Diameter of Printing Tube | 12mm to 35mm | |

| 2 | Length of Printing Tube | 190mm | |

| 3 | Speed Per Min Tube | 60 | |

| 4 | Main Motor | 3HP | |

| 5 | Machine Height | 1500mm approx. | |

| 6 | Machine Width | 1200mm approx. | |

| 7 | Machine Length | 1800mm approx. | |

| 8 | Machine Weight | 2000kgs approx. | |

Machine is designed with manual feed or auto feed by pusher feed mechanism with manual loading of tubes on conveyor, but after printing of tubes take out will be done manually. Fix dug drive speed and fix mandrel drive in manual machine.

Machine is designed with pusher feed mechanism, partition conveyor & vacuum holding while tube auto feed for stable operation. Pick-n-place mechanism to transfer the printed tubes over oven chain for drying process. Oven drive derived from main machine drive for synchronization. We can also provide common drive system to run complete decoration line in synchronization with machine to machine transfer mechanism.