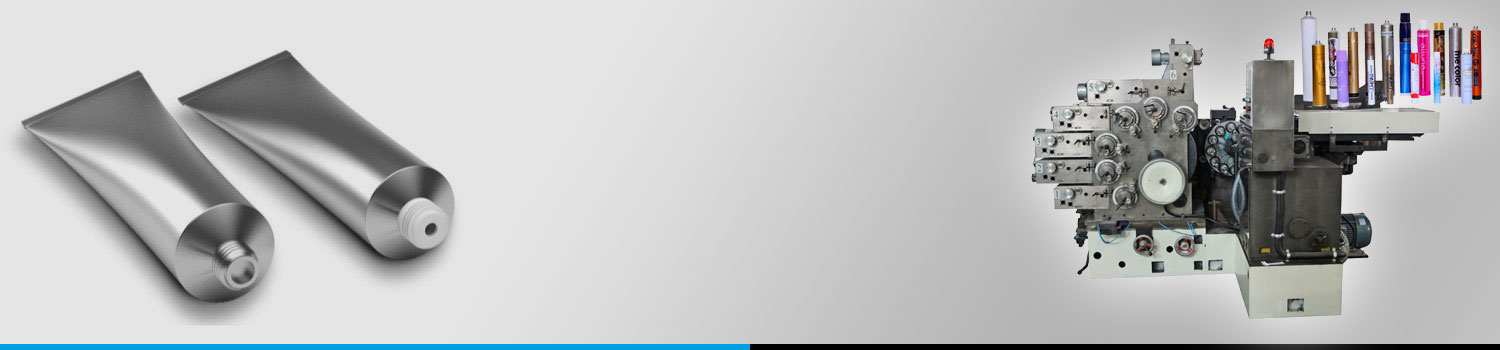

Aluminium Collapsible Tube Line

Drying Oven

The Drying Ovens are specially designed for the Drying of Coated and Printed Tubes. Coating Tubes need more Temperature for drying. The smoke created damages the high gloss of Printing and Coating Finishing on the Tubes, so the other Drying Oven is used for Printed Tubes in which you need less temperature. The machine is designed with Two Drying Ovens for Printing and Coating Machine. The high gloss finish can be obtained only by two separate Drying Ovens. These ovens are designed in auto combustion gas fired unit as well in electric heaters as per client requirement.

| Sr. Nos. | Technical Data | |

|---|---|---|

| 1 | Capacity of Machine | 12mm to 35mm |

| 2 | Length of Drying Tube | 190mm |

| 3 | Speed Per Min Tube | 60 |

| 4 | Main Motor | 1HP |

| 5 | Machine Height | 1400mm approx. |

| 6 | Machine Width | 800mm approx. |

| 7 | Machine Length | 3000mm approx. |

| 8 | Machine Weight | 800Kgs approx. |

| 9 | Temperature Up to | 200 Degrees C approx. |

This machine comes with separate drive 1HP motor & gearbox. Tubes are manually transferred onto pegs of drying oven chain. Drying time is 5mins

This machine has drive from coating or printing machine, if run individually or from common drive for decoration unit for synchronization and automation purpose. Tensioner is provided with oven chain for tightening & stable chain movement. 2mins cooling zone is given for cooling of tubes coming out from oven. Drying time is 7mins.

(a) Chain (b) Idlers (c) Heaters or auto combustion gas unit (d) Pegs